Lead Screw Tappers and Drilling Units

Simple Solutions to Improve Your Productivity

Virtually all lead screw tappers and drilling units can be outfitted with adjustable or fixed center multiple spindle heads. A thorough analysis of your application will reveal if these types of multiple spindle drilling or tapping heads are warranted.

Lead Screw Tapping Unit #1

Standard Features

- Precision Thread Ground Lead Screw and Nut Assembly

- Quick Change of Lead Screw and Nut Assembly

- Tap Jam Limit Switch for No Hole or Undersize Hole Condition

- Alloy Aluminum Main Body

- Large Quill Diameter and Quill Bearings

- All Ball Bearing, Spline Driven

- Oil Tight Limit Switches

- ASA I.D. Spindle

- Mounting for Multi-Spindle Head

- Enclosed Belt Guard

- Conveniently Located Control Dogs

- Adjustable Heavy-Duty Motor Mounting Bracket

- Note: Use of Brake Motor or D.C. Braking is Recommended

Optional Equipment

- Convertible Spindle Nose

- Reverse Mounted Motor Bracket Assembly

- Back Mounted Motor Bracket Assembly

- Air Counterbalance Assembly

- Spindle Drive Brake Motor

- Electrical Controls

- Slide, for Rapid Advance

- Servo Drive Feeds and Controls

- Quick Change Tooling

Lead Screw Tapping Unit #2

Standard Features

- Precision Thread Ground Lead Screw and Nut Assembly

- Quick Change of Lead Screw and Nut Assembly

- Tap Jam Limit Switch for No Hole or Undersize Hole Condition

- Safety Return Override Limit Switch to Prevent Jamming of the Lead Screw

- Alloy Aluminum Main Body

- Large Quill Diameter and Quill Bearings

- All Ball Bearing, Spline Driven

- Oil Tight Limit Switches

- ASA I.D. Spindle

- Enclosed Belt Guard

- Mounting for Multi Spindle Head

- 1: 2.46 Reduction Gear Box Assembly

- Conveniently Located Control Dogs

- Adjustable Heavy-Duty Motor Mounting Bracket

- Note: Use of Brake Motor or D.C. Braking is Recommended

Optional Equipment

- Convertible Spindle Nose

- Reverse Mounted Motor Bracket Assembly

- Pick-Off Speed Change Gear Box

- Air Counterbalance Assembly

- Spindle Drive Brake Motor

- Electrical Controls

- Slide, for Rapid Advance

- Servo Drive Feeds and Controls

- Quick Change Tooling

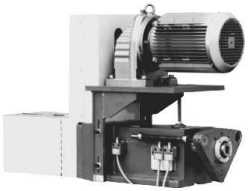

Hydraulic Drilling Unit

Standard Features

- 7 1/2 GPM, Variable Pressure, Variable Volume Vane Type Hydraulic Pump

- Commercial Temperature and Pressure Compensating Feed Valve

- Commercial Directional Valves

- Commercial Sub-Plate Mounted Hydraulic Cylinders

- Alloy Aluminum Main Body

- Large Quill Diameter and Quill Bearings

- All Ball Bearing, Spline Driven

- Oil Tight Limit Switches

- ASA I.D. Spindle

- Enclosed Belt Guard

- Mounting for Multi Spindle Head

- Conveniently Located Control Dogs

- Adjustable Heavy-Duty Motor Mounting Bracket

Optional Equipment

- Separate Pump Drive Assembly

- Peck Feed

- Dual Feed Control

- Forward and Back Feed Control

- Pick-Off Speed Change Gear Box

- Convertible Spindle Nose

- Spindle Drive Motor

- VFD Motor and Controller

- Electrical Controls

- Servo Drive Feeds and Controls

- Quick Change Tooling